Common Structural Mistakes in Floating Bed Frames

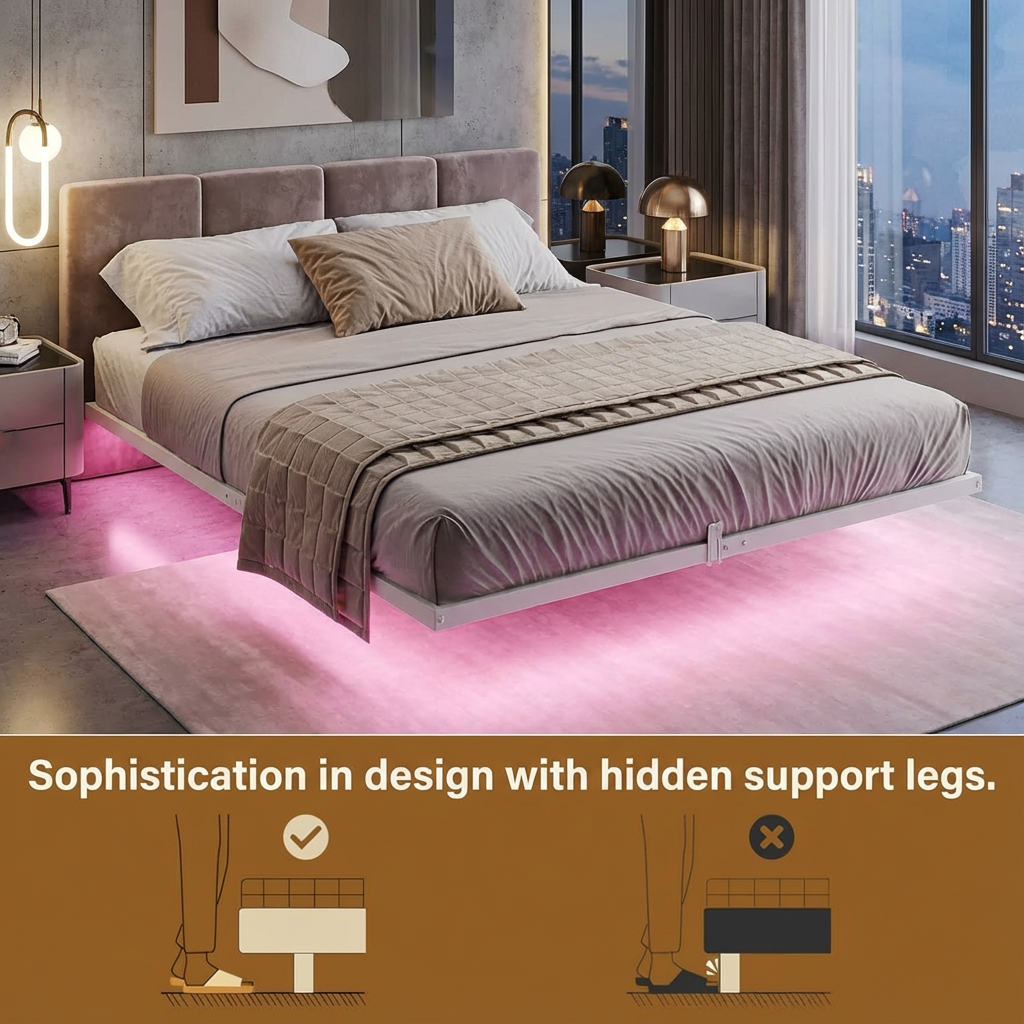

The demand for modern floating bedroom furniture continues to grow, especially for designs such as a floating loft bed, hover bed, floating bunk beds, and compact floating single bed solutions. For B2B buyers, importers, and online sellers, these products offer strong visual appeal and strong market click-through rates. However, because floating structures rely on concealed engineering rather than visible legs, even small structural mistakes can significantly reduce durability, load capacity, and long-term performance.

Understanding these mistakes helps procurement teams choose higher-quality suppliers and avoid costly after-sales issues—particularly critical in online markets where return and replacement logistics can quickly become expensive. Below are the most common engineering errors found in bed floating designs and how professional manufacturers avoid them.

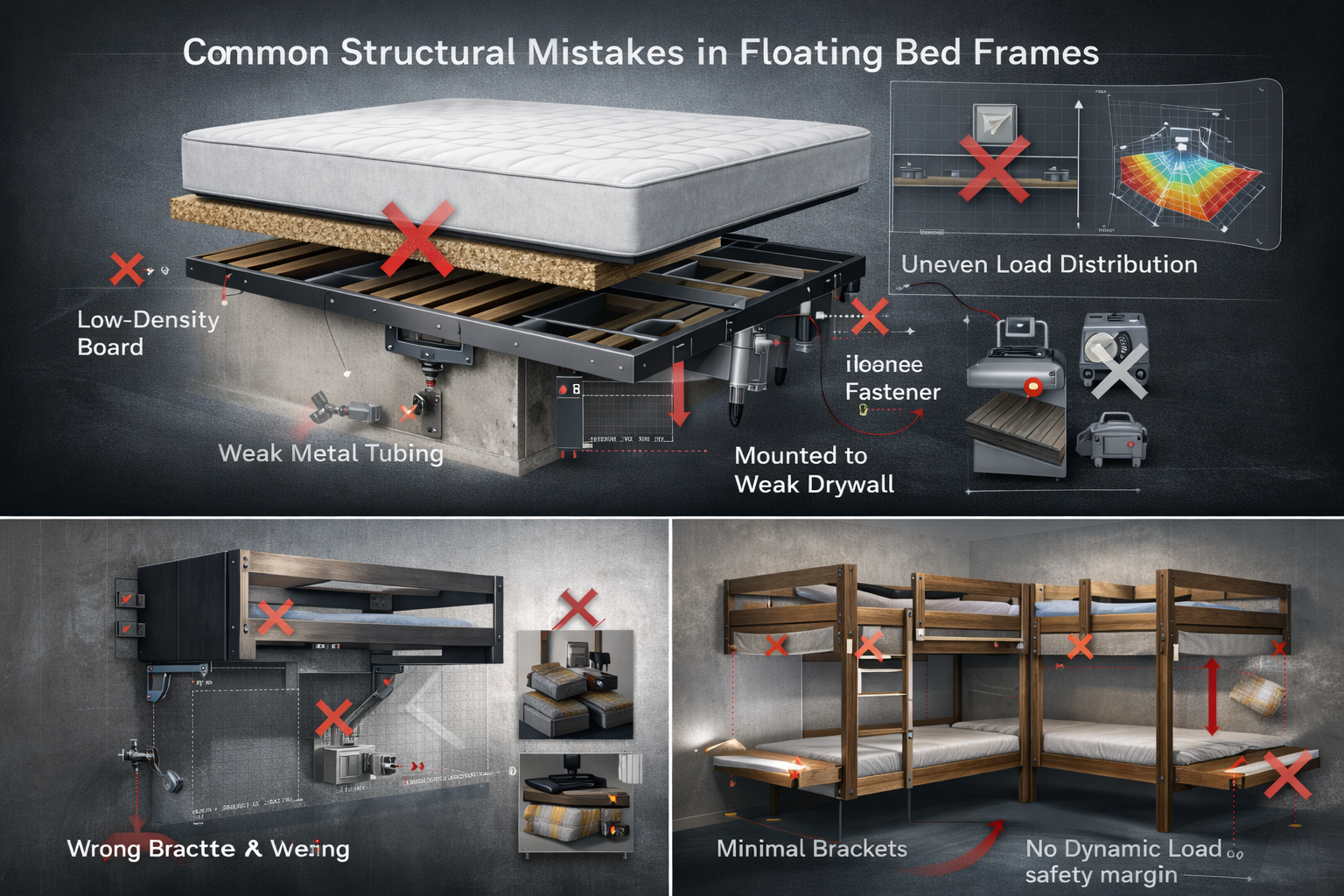

1. Under-Engineered Support Frames

The most frequent mistake in floating bed construction is insufficient structural reinforcement.

Whether the product is a floating loft bed or a floating single bed, the weight of the user must be carried by a hidden steel or hybrid steel-wood frame. Many low-cost designs rely on thin metal tubing or low-density boards, resulting in bending over time.

Impact on B2B sellers:

Increased warranty claims

Negative reviews mentioning noise, wobbling, or sagging

Shorter product lifecycle on e-commerce platforms

A properly designed hover bed or floating bunk beds frame requires thicker steel profiles, cross-bracing, and load-tested fasteners to ensure safe long-term use.

2. Incorrect Load Distribution

Floating beds are visually minimal, but structurally complex.

Because there are no visible legs, the frame must distribute weight evenly across multiple internal support points.

A common mistake is placing too much load toward one side, especially in floating bunk beds and elevated floating loft bed designs.

Symptoms include:

Tilting or minor rotation

Frame distortion after months of use

Difficulty assembling due to misaligned holes

Professional engineering ensures that the bed floating structure spreads load evenly across both longitudinal and transverse directions.

3. Weak Wall-Mounted or Hidden Support Systems

Some floating styles—particularly floating single bed or compact hotel-style hover bed units—use wall-mounted brackets or concealed pedestal bases.

Mistakes include:

Brackets fixed to non-load-bearing walls

Too few attachment points

Use of wood screws instead of structural anchor bolts

For commercial buyers, improper mounting can lead to serious safety issues.

A qualified factory provides installation guides, anchor specifications, and load-tested hardware compatible with different wall materials (concrete, brick, wood studs).

4. Overlooking Dynamic Load Testing

Static weight testing is not enough.

A floating loft bed or floating bunk beds must withstand years of movement, climbing, and repeated stress cycles.

Common mistakes include:

Testing only the center point, ignoring edges

Not simulating children's climbing or jumping (critical for bunk beds)

Not testing torsion or long-term fatigue

A structurally sound bed floating design undergoes:

Static load tests

Dynamic fatigue tests

Edge and corner pressure tests

Fastener torque retention checks

Factories that document and share these results provide stronger assurance for B2B procurement.

5. Poor Material Pairing in Steel-Wood Hybrid Frames

Floating bed designs commonly use a steel base paired with engineered wood components.

Incorrect material combinations—such as low-thickness panels, untreated steel, or incompatible fastener systems—can reduce the lifespan of the hover bed structure.

Typical issues include:

Cracking at connection points

Corrosion on uncoated steel

Noise due to friction between mismatched materials

Premium manufacturing includes:

Powder-coated steel

E1/E0 certified panels

Reinforced connection hardware

Anti-loosening mechanisms

6. Insufficient Safety Margins in Elevated Designs

A floating loft bed or floating bunk beds requires higher structural safety margins due to height and dynamic usage.

A frequent mistake is designing only for the minimum required load, leaving no buffer.

Professional makers build frames to exceed required limits by 30–50%, ensuring safety for a variety of user weights and usage habits.

7. Lack of Clear Assembly Guidance

Even a well-designed floating single bed can fail if the assembly instructions are unclear or overly simplified.

Common oversights:

Missing torque requirements

Incorrect sequence of steps

No warning labels for critical load-bearing screws

B2B buyers benefit from factories that provide:

Clear diagrams

Video guides

QR-code installation manuals

Pre-assembled structural modules to reduce errors

Choose Well-Engineered Floating Beds for Long-Term Success

Working with a manufacturer that prioritizes engineering, testing, and documentation allows you to build a stable, scalable product line with fewer after-sales issues.

If you would like structural drawings, load-testing reports, or OEM/Private Label development support for your floating bed collection, our team is ready to assist your next sourcing project.