Weight Capacity and Load Testing for Modern Floating Beds

For B2B buyers evaluating bedroom furniture, understanding the load-bearing performance of a floating bed frame full size, a full size floating bed, or even a floating bed frame twin is essential. Floating structures deliver a clean, modern aesthetic, and models such as a modern floating bed frame or a floating LED bed have become increasingly popular in both online retail and private-label assortments. However, behind the visual appeal is structural engineering that determines long-term reliability, safety, and customer satisfaction.

Why Weight Capacity Matters in Floating Bed Designs

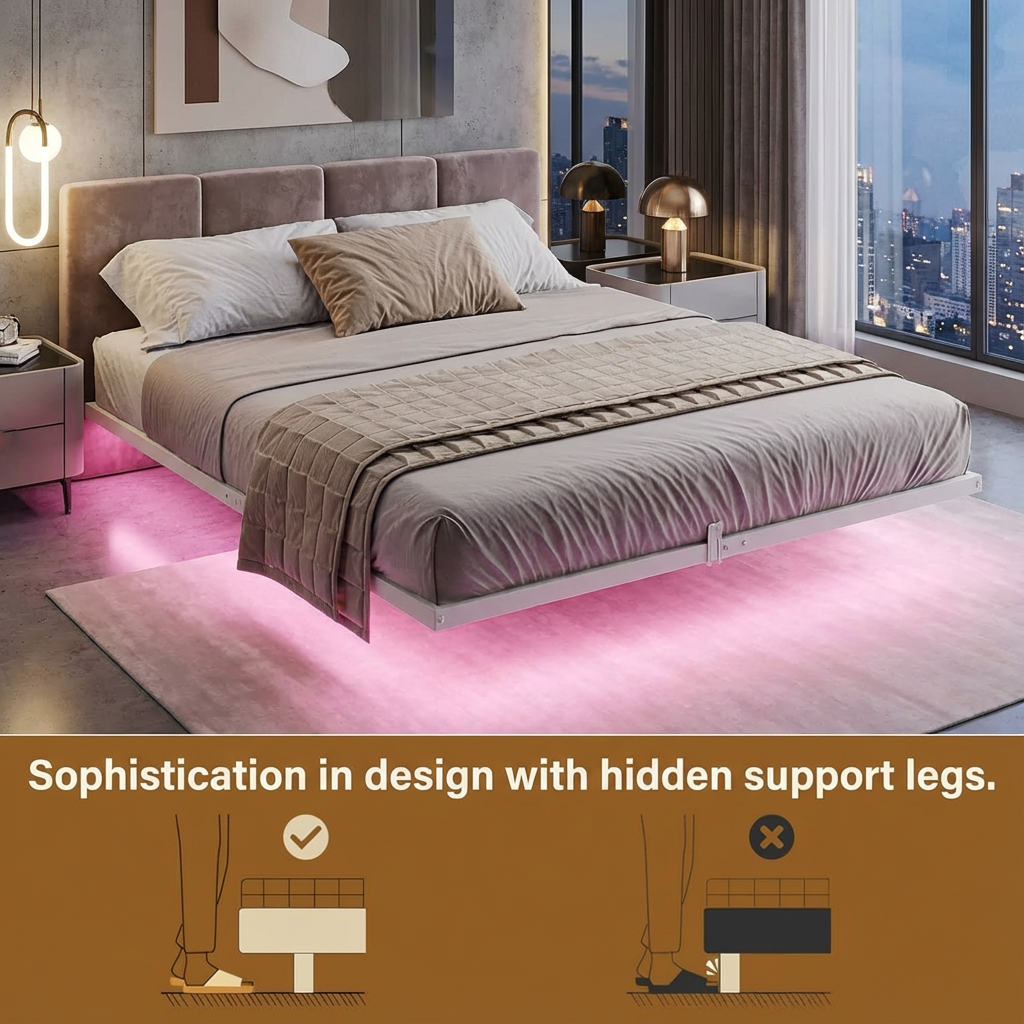

Floating beds rely on concealed base platforms or reinforced steel structures to create the “floating” illusion. Unlike traditional beds with visible legs, the stability depends on controlled force distribution. Whether a buyer sources a full size floating bed or a floating bed frame twin, the weight rating affects product reviews, warranty claims, and overall marketplace performance. A well-engineered floating bed should support dynamic movements, uneven loading, and long-term fatigue without deformation.

How Load Testing Is Conducted

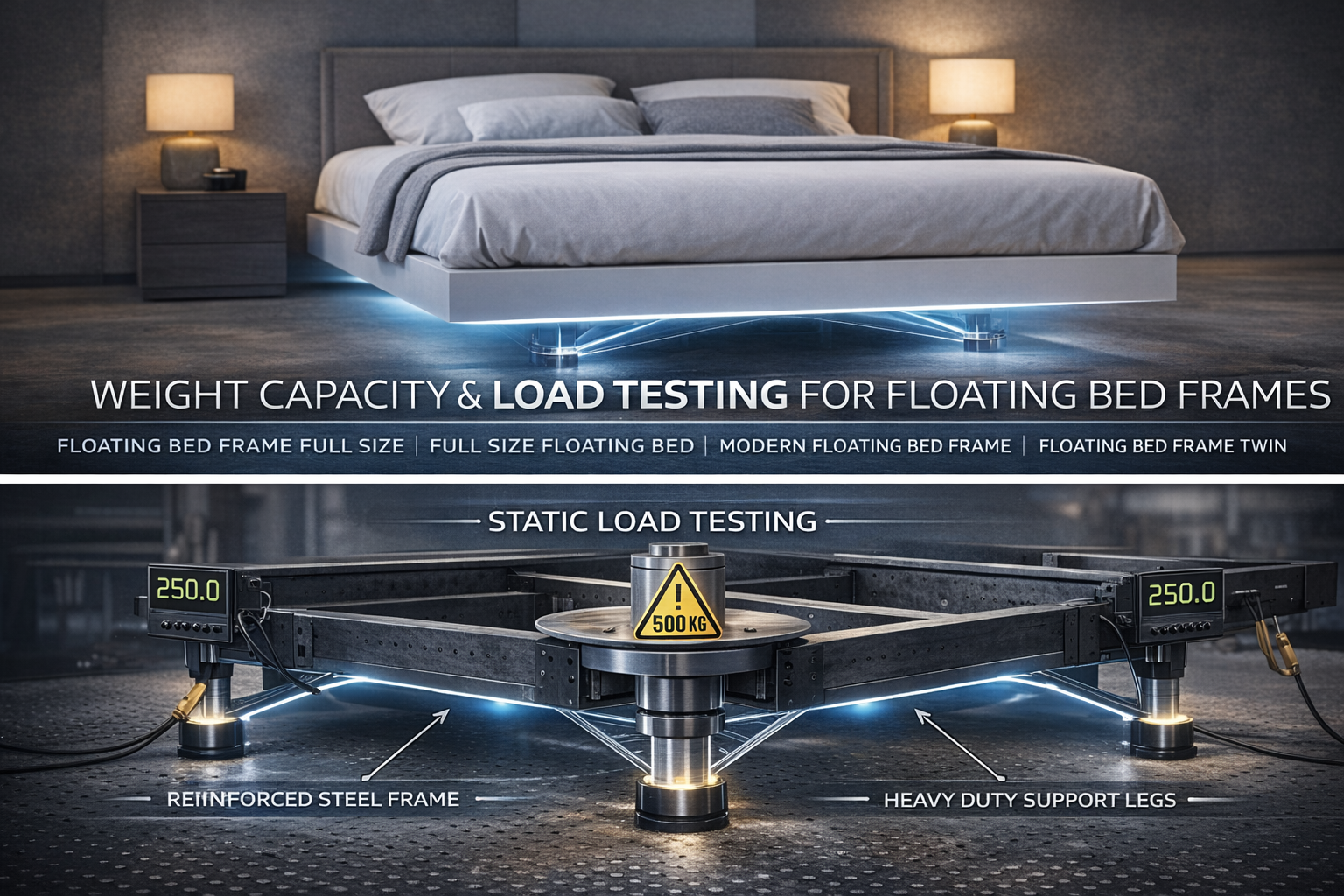

Professional manufacturers conduct mechanical load testing to verify the structural integrity of a floating bed frame full size or floating LED bed. Testing typically includes:

1. Static Load Testing

A controlled weight is applied to the center and edges of the bed platform. For a modern floating bed frame, this ensures the steel-wood structure maintains rigidity even under high pressure.

2. Dynamic Load Simulation

Machines simulate repeated sitting, lying, and shifting motions. This helps verify real-world durability for products sold online, where return and replacement logistics are costly for B2B buyers.

3. Edge & Corner Stress Testing

Floating designs require reinforced sections to handle side pressure. Whether the model is a full size floating bed or a floating bed frame twin, these points must withstand everyday usage habits without wobbling.

4. LED-Integrated Structure Verification

For a floating LED bed, additional testing ensures that the lighting components do not affect structural strength, wiring safety, or long-term stability.

Material Selection and Its Impact on Load Capacity

A strong weight rating is only possible with proper material engineering.

Manufacturers typically rely on:

Powder-coated steel frames for hidden structural support

E1 or FSC-certified engineered wood panels

Anti-corrosion treatment for long-term use

Precision welding and reinforced joints at stress-bearing points

These factors together allow a floating bed frame full size or modern floating bed frame to carry higher loads while maintaining the sleek floating illusion.

Typical Load Ratings for Different Floating Bed Models

Although load ratings vary by design, here are common benchmarks in the global market:

Floating Bed Frame Twin: 250–300 kg

Full Size Floating Bed: 300–350 kg

Floating LED Bed (enhanced frame): 350–400 kg

Premium Reinforced Floating Bed Frame Full Size: 400–450 kg

Accurate ratings depend on structural design, testing method, and frame material.

Why Load Testing Matters for B2B Sellers

Importers, distributors, and online sellers choose floating beds because of their modern aesthetic and strong consumer appeal. However, weight capacity issues can quickly lead to:

High return rates

Negative online reviews

Increased after-sales costs

Reduced listing credibility on Amazon, Wayfair, Shopify, or local platforms

By selecting a partner with transparent load testing and mature engineering, B2B buyers can mitigate risks and build a long-term stable assortment.

Build a Reliable Floating Bed Assortment With Proven Engineering

If you would like engineering drawings, detailed test reports, or OEM/Private Label solutions for your upcoming collection, our team is ready to support your next project.