As metal beds continue to dominate international furniture markets—especially in Europe, North America, and Southeast Asia—bulk buyers must understand how to evaluate quality before placing large orders. Whether you are an importer, wholesaler, or e-commerce brand, the quality checkpoints you verify upfront will directly impact your margins, customer reviews, and long-term supplier partnership.

Here are the essential quality points every buyer should check before confirming a bulk order.

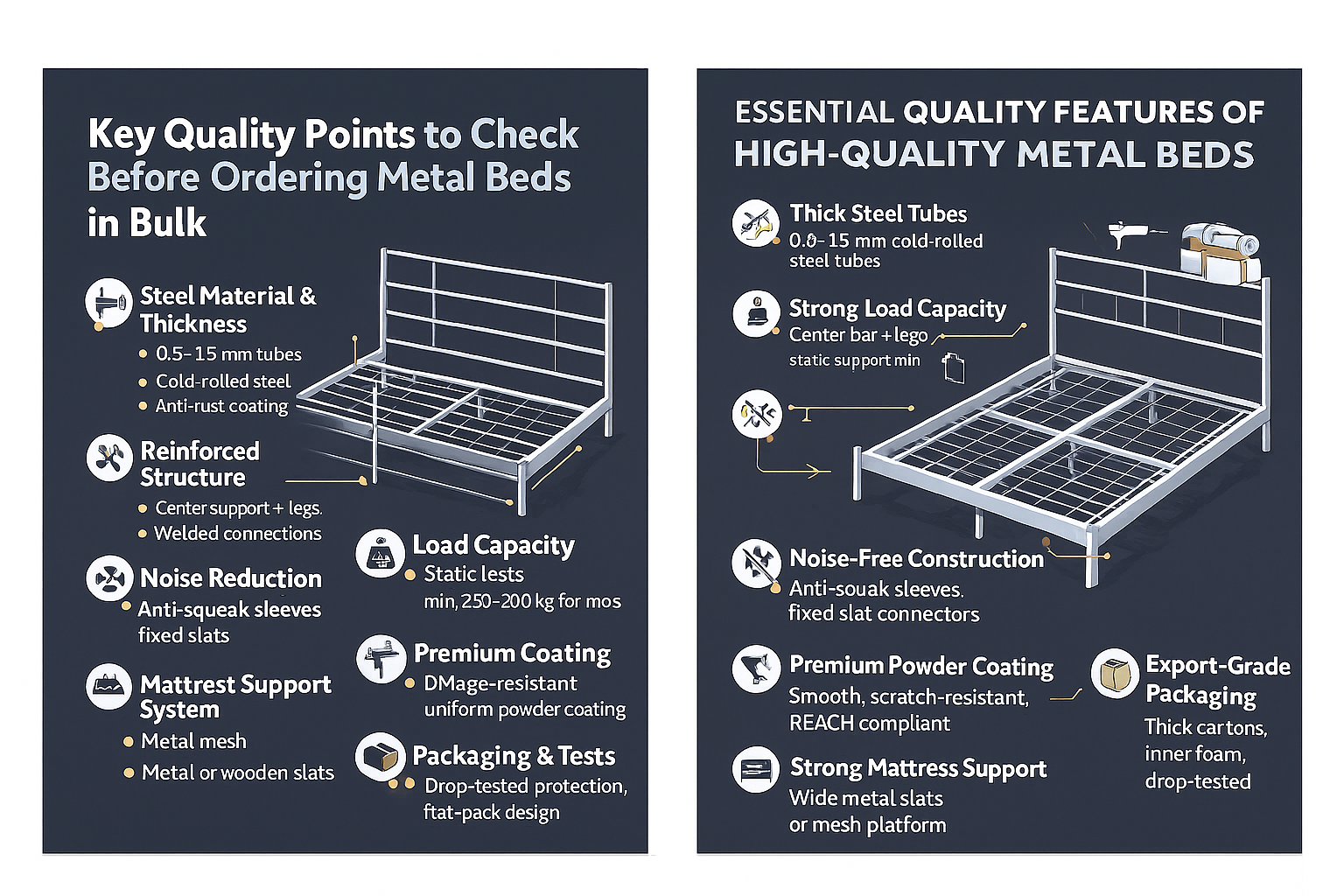

1. Steel Material and Thickness

The foundation of every metal bed is the steel itself.

What to check:

Tube wall thickness:

Standard frames: 0.8–1.2 mm

Heavy-duty frames: 1.2–1.5 mm

Steel grade: high-quality cold-rolled steel

Rust prevention: phosphating + uniform powder coating

Consistency: same steel thickness across all bars

Weak or thin material is the #1 cause of instability, bending, and frame noise over time.

2. Structural Reinforcement and Load Capacity

A good design should balance aesthetics with engineering.

Look for:

Center support bar + middle legs for Full/Queen/King

Reinforced side rails with extra welding points

A stable connection between headboard, footboard, and frame

Verified static load capacity (at least 250–300 kg for household use)

This ensures long-term performance and minimizes complaints.

3. Noise-Free Construction

Noise is one of the biggest sources of bad reviews for metal beds—especially on Amazon and Wayfair.

Quality indicators:

Anti-noise rubber or plastic sleeves at metal-to-metal contact points

Fixed slats that do not shift during use

Tight screw connections that don’t loosen easily

Brackets that eliminate structural shaking

A truly silent frame is always a bestseller.

4. Mattress Support System

The mattress support determines comfort and durability.

Options:

Metal mesh platform: strong, heavy-duty

Metal slats: balanced support, very stable

Wooden slats: flexible and comfortable, but packaging-sensitive

What to check:

Slat distance consistency

Proper fixation to avoid noise

Adequate number of slats for your market standard

Poor support leads to sagging mattresses and early returns.

5. Surface Treatment & Powder Coating

A premium appearance often reflects premium workmanship.

Inspect:

Smooth, even powder coating

No scratches, bubbles, or “orange peel” texture

Low smell (REACH or RoHS compliant)

Color consistency across all components

High-quality coating protects against rust and enhances aesthetics for modern homes.

6. Hardware & Assembly Experience

In bulk orders, assembly quality directly affects the customer’s experience and review rating.

High-quality indicators:

Pre-drilled holes aligned perfectly

Hardware packs sorted and labeled

Spare screws included

Assembly instructions clear and multilingual

Assembly time under 20–30 minutes

Easy assembly = fewer returns + happier customers.

7. Packaging Strength and Drop Test

Packaging determines whether the bed arrives safely—especially for e-commerce.

Confirm:

Strong K-grade export cartons

Corner protectors, foam blocks, and protective wrapping

ISTA-certified drop test results

Clear labels and barcodes

Flat-pack design optimized for container loading

Good packaging reduces logistics risk and protects your margins.

8. Compliance and Documentation

For Europe and North America, certifications can be mandatory.

Ask for:

REACH compliance (chemical safety)

RoHS compliance

FSC certification for wooden slats (if used)

Load-testing reports

Full material specification sheets

A reliable supplier should provide documents proactively.

9. Supplier Capacity and Stability

Even the best samples are meaningless if the factory cannot deliver consistent quality.

Evaluate:

Monthly production capacity

Peak-season ability

OEM/ODM development capability

Their export experience in your target market

Response speed during sampling & negotiation

Choosing the right supplier is often more important than the product itself.

Bulk metal bed orders require careful evaluation across material, structure, coating, assembly, packaging, and supplier reliability. By checking these key quality points, buyers can significantly reduce risk, minimize after-sales issues, and build sustainable product lines that perform well across global markets.