This guide helps wholesale buyers evaluate metal beds from a professional, B2B perspective, so you can select the right supplier and avoid costly mistakes.

1. Clarify Your Target Market and Usage Scenario

Before checking any technical details, define clearly:

Target market: Europe, North America, Middle East, Southeast Asia, etc.

End users: students, young families, tenants, hotels, dormitories, or e-commerce buyers.

Price segment: entry-level, mid-range, or premium.

These choices will influence bed size standards, weight capacity, coating requirements, packaging level, and even the style of the headboard.

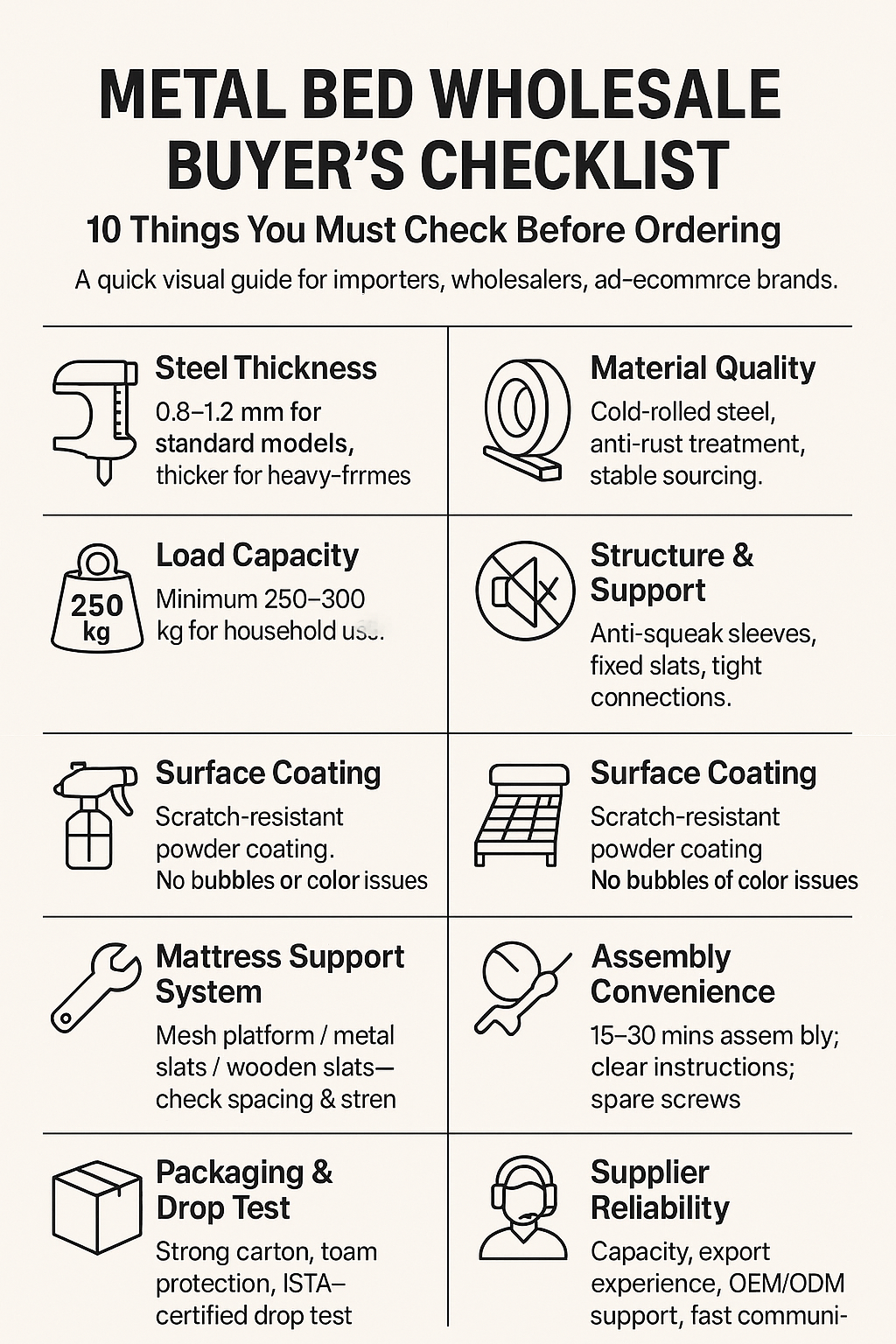

2. Check the Steel Material and Thickness

High-quality metal beds begin with the right steel specification.

Key points to confirm:

Tube thickness (wall thickness):

Main legs and side rails usually 0.8–1.2 mm for standard models, thicker for heavy-duty designs.

Steel grade: cold-rolled steel or high-quality carbon steel is preferred for stability.

Anti-rust treatment: phosphating, powder coating quality, and salt-spray resistance if needed.

Ask your supplier for detailed material specifications and, if possible, a sample cut of the tube to verify thickness.

3. Evaluate Structural Design and Load Capacity

A visually minimal frame can still be structurally strong—if designed correctly.

Focus on:

Number and spacing of support slats or mesh grid.

Central support: middle bar + legs for Full/Queen/King sizes.

Corner connections: use of reinforced brackets, extra welding points, or screw plates.

Test load capacity:

Ask for static and dynamic load test reports.

For general household use, many buyers require at least 250–300 kg combined load.

A good supplier can show drawings or test videos to prove the structure is not just “beautiful,” but engineered.

4. Confirm Noise and Stability Performance

Noise and shaking are the main reasons for bad reviews online.

Check:

Connection method:

Bolt + nut + washer design is more stable than simple self-tapping screws.

Anti-noise features:

Plastic or rubber sleeves at metal-to-metal contact points.

Additional brackets to prevent movement between slats and frame.

Floor protection:

Plastic foot caps to avoid scratching floors and improve grip.

When you receive a sample, assemble it and test by shaking, sitting, and lying down. A high-quality metal bed should feel solid with minimal squeaks.

5. Review Surface Treatment and Color Options

Surface quality affects both appearance and corrosion resistance.

Ask about:

Type of coating: high-quality powder coating is standard for export metal beds.

Color options: matte black, white, industrial grey, gold, or customized RAL colors.

Scratch resistance: light rubbing with a coin or metal item should not easily remove the coating.

Uniform, smooth coating with no rough spots, bubbles, or color differences is a sign of stable production.

6. Inspect Slats and Mattress Support System

The mattress support system is critical for comfort and durability.

Options include:

Metal mesh / metal slats: very durable, good support.

Wooden slats (often poplar or birch): more flexibility and comfort.

Key points:

Distance between slats should follow your market’s mattress requirements.

Slats must be fixed firmly to the frame to avoid noise and movement.

Check whether additional center legs are included for larger sizes.

7. Evaluate Assembly Experience and Hardware

For wholesale and e-commerce, easy assembly can make or break a product.

Look at:

Assembly time: ideally 15–30 minutes for one person with basic tools.

Instruction manual: clear diagrams, multiple languages, and step-by-step layout.

Hardware kit: clearly labeled, individually packed, and with spare screws included.

Ask your supplier to provide 3D assembly videos or PDF manuals. This support greatly reduces after-sales issues.

8. Packaging, Carton Design, and Drop-Resistance

Good packaging protects your margin.

Important factors:

Carton strength: suitable K-grade corrugated board for export.

Internal protection: foam, corner protectors, cardboard partitions to prevent steel parts from rubbing.

Drop test: ask if the product passes standard drop tests (e.g., ISTA).

Labeling: clear product code, size, color, barcode, and shipping marks for warehouse convenience.

Efficient flat-pack design lowers freight cost and increases container loading, improving competitiveness.

9. Check Certifications and Compliance

Depending on the target market, you may need:

REACH / RoHS compliance for coatings and materials.

FSC for wooden slats if required by clients.

EU, UK, or local safety standards if applicable.

A professional manufacturer can prepare compliant documentation and test reports upon request.

10. Assess Supplier Capacity and Service

A high-quality product still needs a reliable partner behind it.

Key questions:

Monthly production capacity and peak-season planning.

Experience in exporting to your target market (Europe, North America, etc.).

Ability to support OEM / ODM, private label, and custom packaging.

Response speed on quotation, samples, and after-sales support.

Long-term cooperation is easier with a supplier who understands B2B communication and project management.

Choosing a high-quality metal bed for wholesale is not just about appearance or price. It requires a clear understanding of material quality, structural design, noise control, surface treatment, assembly, packaging, and supplier capability.

By using this buyer’s guide as a checklist, importers and brands can:

reduce risk in large orders

minimize returns and complaints

build stable bestsellers in their local market

Metal beds will continue to be a strategic category in global furniture trade—and selecting the right model and supplier is the first step to long-term success.