Whether developing a wooden floating bed frame, a white floating bed, or a floating bed frame king size, the success of the product depends on engineering rather than appearance alone.

A floating bed is not designed to truly levitate. Its visual effect is achieved through precise structural planning, hidden support systems, and carefully selected materials. For importers, wholesalers, and online sellers, understanding this engineering logic is essential when evaluating long-term product viability.

Structural Foundation: Where Stability Really Comes From

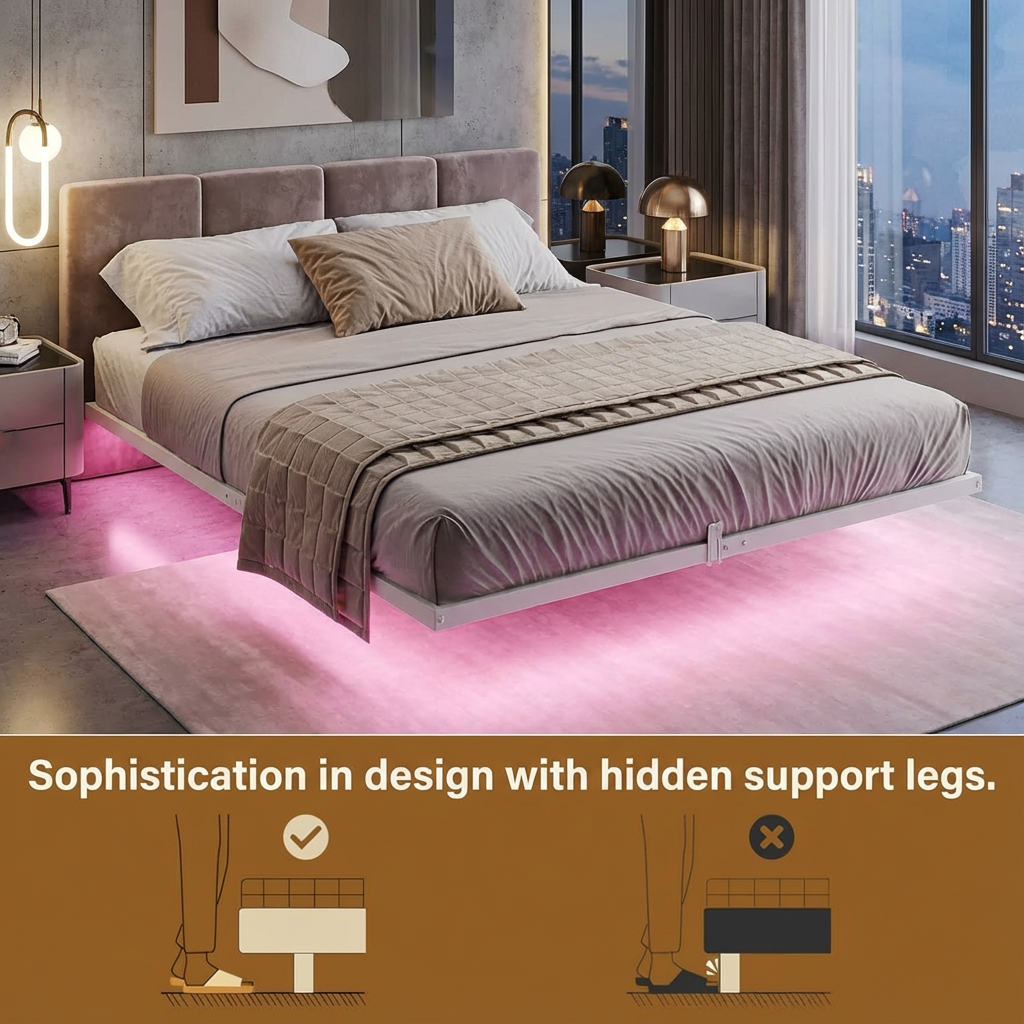

At the core of a stable floating bed frame is a concealed load-bearing platform. Instead of placing legs at the outer corners, the structure shifts support inward, allowing the perimeter of the bed to appear suspended. This approach is widely used across black floating bed and white finishes alike, as color choice does not affect structural performance.

In a wooden floating bed frame, the visible panels are typically supported by an internal steel frame. Steel crossbars distribute weight evenly across the central base, preventing sagging and eliminating movement over time. This same foundation supports larger formats such as a floating bed frame king size, where weight distribution becomes even more critical.

Material Combination: Wood Aesthetics with Steel Strength

Many buyers prefer the warmth of wood finishes while expecting the durability of metal construction. For this reason, most wooden floating bed frame designs rely on a hybrid structure. Decorative wood panels are attached to a reinforced steel skeleton, ensuring long-term stability without compromising visual appeal.

The same engineering applies to a white floating bed, where surface coatings and panel finishes are selected for aesthetic consistency rather than structural function. From a manufacturing standpoint, this separation of structure and appearance allows for efficient customization across different markets.

Storage Integration Without Compromising Balance

A floating bed frame with storage presents additional engineering challenges. Storage compartments must be positioned in a way that maintains the center of gravity while keeping support elements hidden. This is typically achieved by integrating drawers or compartments within the central base rather than extending weight toward the outer edges.

When properly designed, a floating bed frame with storage can offer practical value without reducing stability. For B2B buyers, this feature expands market appeal while preserving the floating visual identity that differentiates the product.

Size Scaling: From Standard to King Size Frames

Scaling a floating bed design from standard sizes to a floating bed frame king size requires more than simply enlarging dimensions. Additional internal bracing, thicker steel profiles, and reinforced joints are introduced to handle increased load.

This engineering consistency ensures that both a black floating bed and a white variant perform identically, regardless of size. For OEM and private label programs, this scalability supports efficient production planning and consistent quality across collections.

Safety, Testing, and Long-Term Use

For commercial markets, safety is inseparable from stability. A well-engineered floating bed undergoes static load testing, dynamic movement simulation, and long-term durability evaluation. These tests ensure that a wooden floating bed frame or floating bed frame with storage remains silent, rigid, and secure throughout its lifecycle.

Professional production standards distinguish factory-built floating beds from conceptual or DIY designs, which often lack proper reinforcement and testing.

Engineering as a Competitive Advantage

From a B2B perspective, the engineering behind a floating bed frame is what transforms a design trend into a reliable product category. A white floating bed or black floating bed may attract attention visually, but only a solid internal structure ensures repeat orders and long-term market success.

B2B Perspective

The stability of a floating bed frame is not accidental—it is the result of deliberate engineering decisions. By combining steel reinforcement, concealed support systems, and scalable design logic, modern floating beds deliver both visual impact and structural reliability.

If you are developing or sourcing floating bed frames for OEM, private label, or online retail projects, early discussions around structure and engineering standards can help ensure a successful launch.

Our team is available to support product evaluation, customization planning, and technical alignment based on your target market requirements.