When sourcing metal beds for the global market, buyers often focus on structure, steel thickness, welding, and overall design. However, one critical factor that significantly determines long-term durability—and customer satisfaction—is powder coating, the protective finish applied to the surface of the metal.

Whether you are purchasing a classic vintage metal bed frame, a modern queen metal frame, or high-volume items like metal bunk beds twin over twin, understanding the importance of powder coating is essential for quality control and brand reputation.

1. Powder Coating Is the First Line of Defense Against Rust

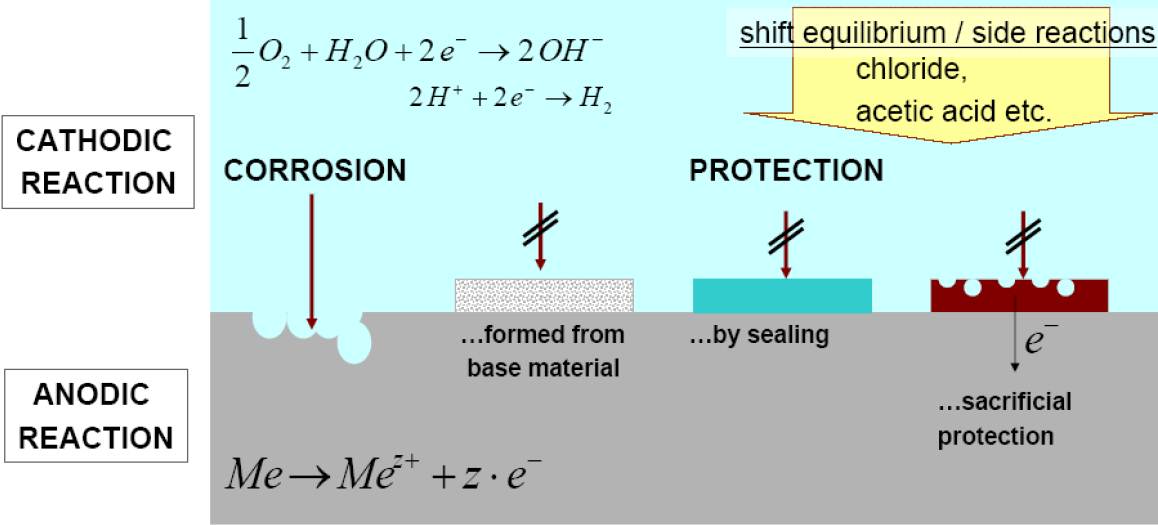

Metal furniture is constantly exposed to environmental factors such as humidity, cleaning chemicals, and daily friction. Powder coating creates a hard, protective layer that seals the steel surface and prevents oxidation. Without proper coating preparation, even high-quality steel will eventually rust.

What importers should check:

Pre-treatment process (chemical wash, phosphating, sandblasting)

Coating thickness (typically 60–90 μm for durable furniture)

Uniformity across joints and corners

Salt-spray test results to evaluate corrosion resistance

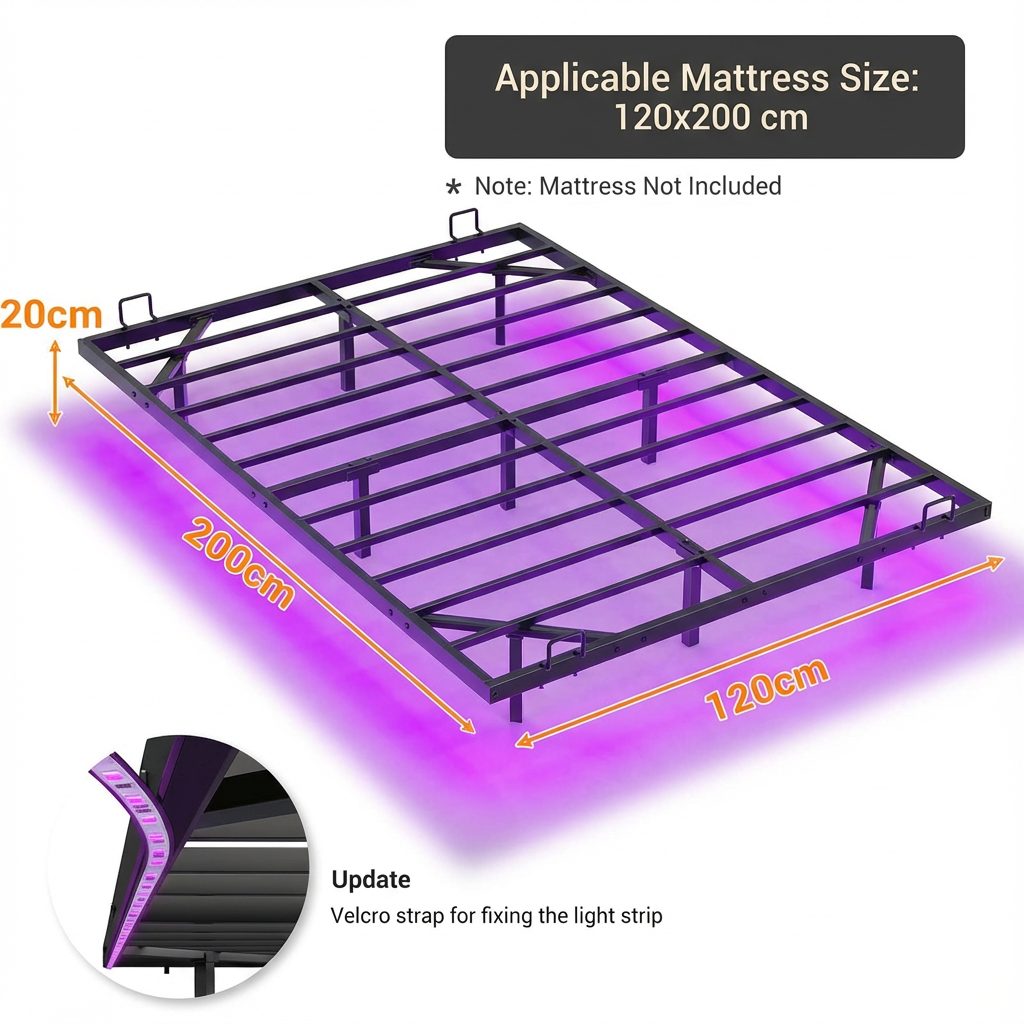

For products used in high-moisture rooms, such as a metal bed frame with storage, strong anti-rust performance is crucial to prevent customer complaints.

2. Powder Coating Enhances Aesthetics and Market Appeal

Color consistency is a key selling point, especially for modern bedroom categories. A well-applied powder coating ensures smooth, even finishes that do not fade or peel over time. This is important both for minimalist items like a full size metal bed and decorative models such as a vintage metal bed frame.

Powder coating advantages for visual quality:

Rich, uniform color

Anti-scratch surface

Soft-touch or matte finishes available

Long-lasting color even under sunlight

In competitive markets like Europe and North America, customers often judge a product’s value by appearance—making surface treatment a major differentiating factor.

3. Stronger Resistance to Daily Wear and Load Stress

Metal beds are functional furniture pieces that undergo daily use. Over time, weak coatings can chip, exposing the steel underneath and accelerating corrosion. A good powder coating layer improves surface hardness, reduces wear, and adds long-term structural protection.

This is particularly important for high-load or multi-user models like metal bunk beds twin over twin, which are frequently used in hostels, student apartments, and rental properties.

Benefits of high-durability powder coating:

Prevents metal-to-metal abrasion

Reduces noise caused by friction

Slows long-term wear from mattress movement

Extends the product lifespan

When buyers compare suppliers, coating performance often predicts how well the bed will age during years of use.

4. Enhanced Safety and Eco-Friendliness

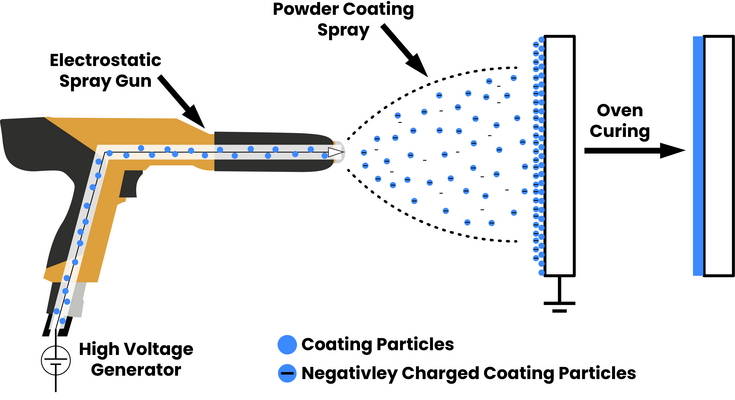

Unlike traditional liquid paint, powder coating contains no volatile organic compounds (VOCs), making it safer for both workers and end consumers. In addition, powder coating adheres without solvents, improving eco-friendliness and compliance with strict environmental standards in Europe and the United States.

Safety advantages:

No harmful chemical emissions

Heat-curing creates a stable, non-toxic finish

Better for children's beds, rental units, and hospitals

This is a major selling point when marketing clean, safe furniture—especially in categories like queen metal frame beds commonly used in family bedrooms.

5. Why Surface Treatment is a Key Part of Factory Capability

Experienced importers know that powder coating quality can vary greatly from one factory to another. Professional metal bed manufacturers invest heavily in automated spraying lines, pre-treatment equipment, and curing ovens to ensure consistent surface treatment.

What to evaluate when auditing a factory:

Size and type of coating line (automatic vs. manual)

Pre-treatment tanks and processes

Powder quality from reputable suppliers

Curing oven temperature accuracy

On-site QC checks for thickness and adhesion

A factory that can deliver stable, high-quality coating is more likely to produce durable metal beds—whether it's a full size metal bed, queen metal frame, or custom-designed metal bed frame with storage.

Powder Coating Is Not Just a Finish—It's a Performance Guarantee

For importers, distributors, and online sellers, powder coating directly affects product lifespan, visual appeal, after-sales performance, and customer reviews. A beautiful surface finish may attract buyers, but a well-executed powder coating ensures long-term satisfaction.

Whether you source a vintage metal bed frame, a practical metal bed frame with storage, or high-capacity metal bunk beds twin over twin, choosing a supplier with strong powder coating capability is essential for delivering reliable, market-ready products.

If you need support evaluating coating quality or selecting a manufacturer with advanced surface treatment technology, our team provides full assistance and OEM/ODM customization tailored for global B2B clients.