As floating bed designs continue to gain popularity in global bedroom furniture markets, customization has become a key requirement for B2B buyers. From led floating bed collections designed for online retail to engineered floating frame bed solutions for contract or hotel projects, flexibility in design and structure plays a critical role in commercial success.

This article explains what can realistically be customized in a floating bed frame wood program and how professional manufacturers support importers, wholesalers, and online sellers through scalable OEM solutions.

1. Why Customization Matters in Floating Bed Programs

Unlike standard platform beds, floating beds rely on concealed structures to achieve their visual effect. As a result, every floating frame bed must balance appearance, strength, and production feasibility.

For B2B buyers, customization helps to:

Align with regional market preferences

Differentiate private-label collections

Control cost, packaging, and logistics

Improve online conversion and brand identity

Whether developing a twin size floating bed frame or a double floating bed frame, customization is often the deciding factor between a generic product and a successful long-term SKU.

2. Frame Structure and Support System Customization

One of the most important customizable elements is the internal structure.

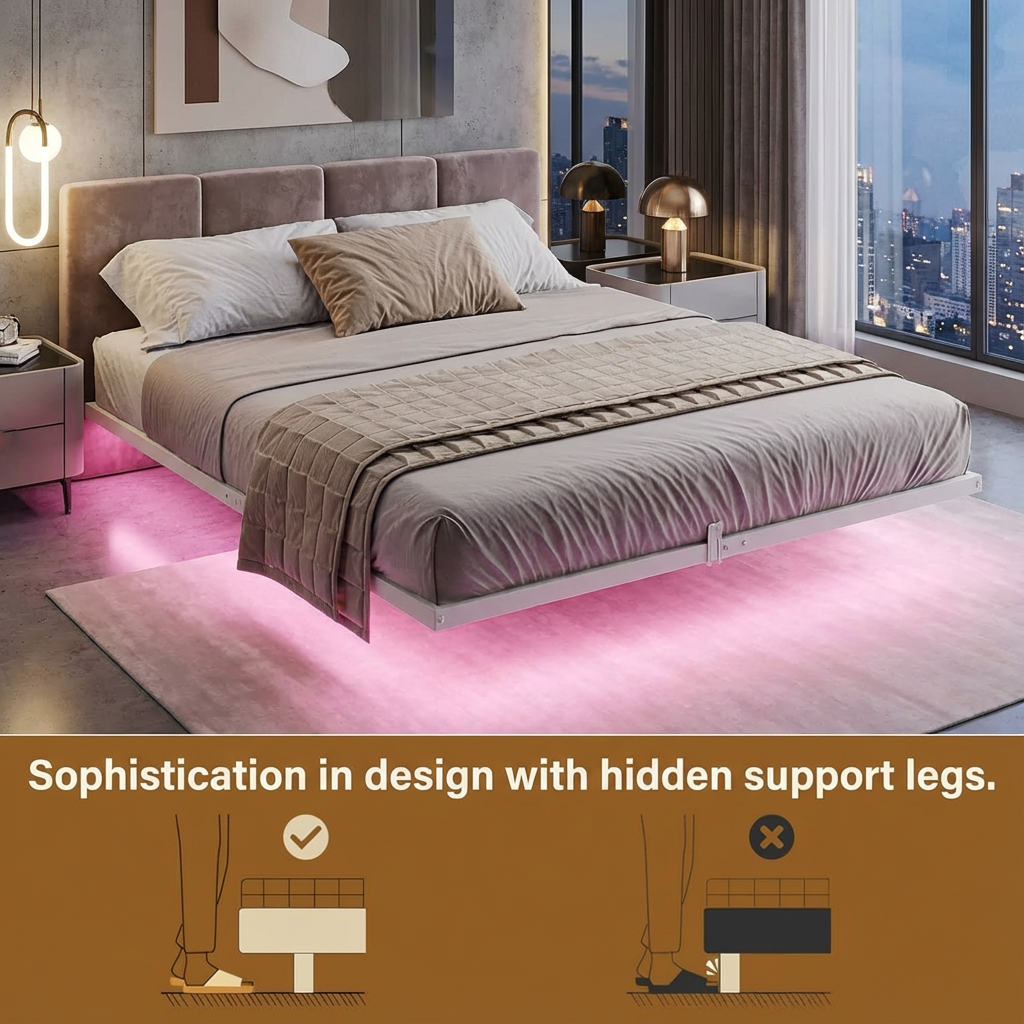

Hidden Support Legs

Position and number of hidden legs can be adjusted

Reinforced layouts for heavier double floating bed frame models

Optimized leg placement for stability and anti-tilt performance

Steel & Wood Combination

A floating bed frame wood design typically combines steel reinforcement with engineered wood panels. Manufacturers can modify:

Steel tube thickness

Reinforcement layout

Wood panel density and thickness

These changes allow the same floating frame bed design to serve different market segments.

3. Size Variations and Load Requirements

Floating beds are not “one-size-fits-all” products.

Twin size floating bed frame

Ideal for compact spaces, youth rooms, or urban apartments. Structural design focuses on stability with minimal material use.Double floating bed frame

Requires higher load capacity and reinforced center structure, especially for export to Europe and North America.

Manufacturers often share a common design language across sizes while adjusting internal engineering to maintain performance consistency.

4. LED System and Functional Add-Ons

A led floating bed adds strong lifestyle appeal but also introduces technical considerations.

Customizable LED elements include:

Warm or cool lighting color temperature

Side glow vs. under-bed illumination

Wiring channel design integrated into the floating frame bed

Power supply standards for different regions

Proper LED integration ensures safety, ease of assembly, and long-term durability.

5. Surface Finish and Visual Customization

Visual customization is often the most visible differentiation point.

For floating bed frame wood designs, buyers may customize:

Wood grain color and texture

Matte or textured finishes

Edge profiles and corner details

Upholstered or panel-style headboards

These changes allow the same core floating frame bed to fit different brand aesthetics, from minimalist to premium.

6. Packaging and Logistics Adaptation

From a B2B perspective, customization is not limited to the product itself.

Manufacturers can adapt:

Flat-pack structure for container optimization

Carton size and labeling

Assembly instructions for online sellers

This is especially important for scalable twin size floating bed frame and double floating bed frame programs intended for e-commerce distribution.

7. What B2B Buyers Should Confirm Before Customization

Before launching a customized floating bed project, buyers should confirm:

Structural changes do not affect weight capacity

LED systems comply with local regulations

Modified designs are validated with testing

Production timelines align with market launch plans

A professional supplier will guide buyers through these steps rather than offering purely visual customization.

Customization as a Competitive Advantage

For B2B buyers, choosing the right customization partner ensures that every floating frame bed, from led floating bed designs to double floating bed frame models, delivers both visual impact and commercial reliability.

Light B2B CTA

If you are planning a custom floating bed collection or upgrading an existing program, working with a manufacturer experienced in structural customization and OEM development can help reduce risk and accelerate your go-to-market process.

Feel free to contact us to discuss specifications, engineering options, or private-label solutions tailored to your target market.