In the world of custom furniture manufacturing, innovation begins long before production starts. Every successful product is the result of thoughtful design, precise engineering, and close collaboration between the client and manufacturer. At Delux Furniture, our product development process transforms a simple sketch into a high-quality sample—ready for mass production and global distribution.

We believe that transparency and customization are the keys to building strong partnerships with our B2B clients. Here’s how our development process brings ideas to life, step by step.

1. Concept & Design Consultation

Every project starts with a concept. Clients share their ideas, reference photos, or mood boards to help our design team understand their goals. Whether it’s a new storage rack, coffee table, or steel-wood furniture set, we analyze the functional requirements, target market, and aesthetic preferences.

Our design experts then create initial sketches and digital mockups, using tools like 3D modeling software and AI-assisted rendering. This allows clients to visualize proportions, materials, and finishes before any prototype work begins. Early collaboration ensures that each design aligns with both brand identity and market expectations.

2. Technical Development & Material Selection

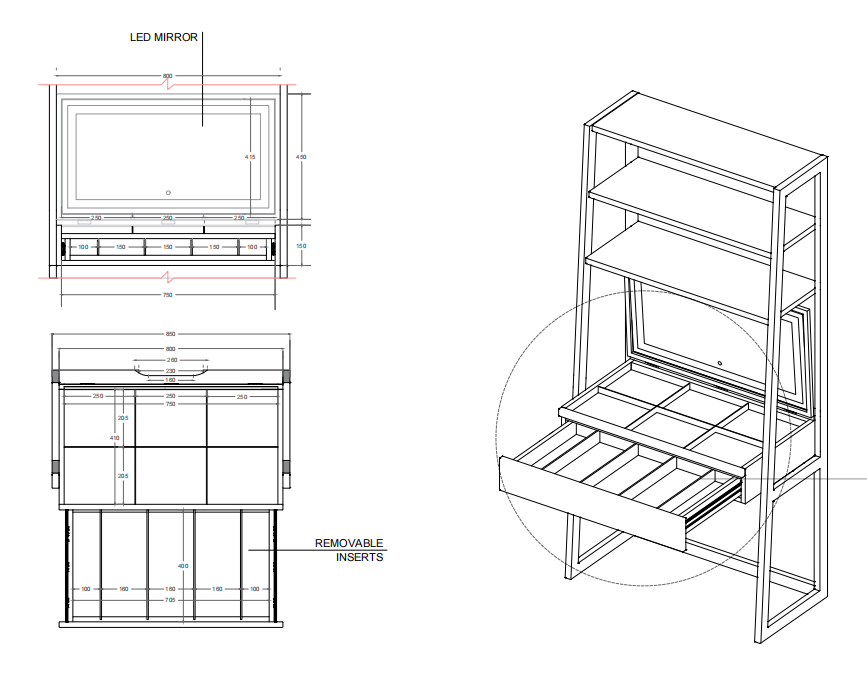

Once the concept is confirmed, our engineers convert the design into precise technical drawings and 3D models. These blueprints define every measurement, connection, and joint, ensuring the structure is both elegant and durable.

At this stage, we also select materials according to the product’s use case. For instance:

Steel frames for strength and stability

Melamine or veneer boards for surface beauty and durability

Powder coatings for corrosion resistance

Eco-friendly panels to meet sustainability requirements

Material testing guarantees that each component meets safety and performance standards.

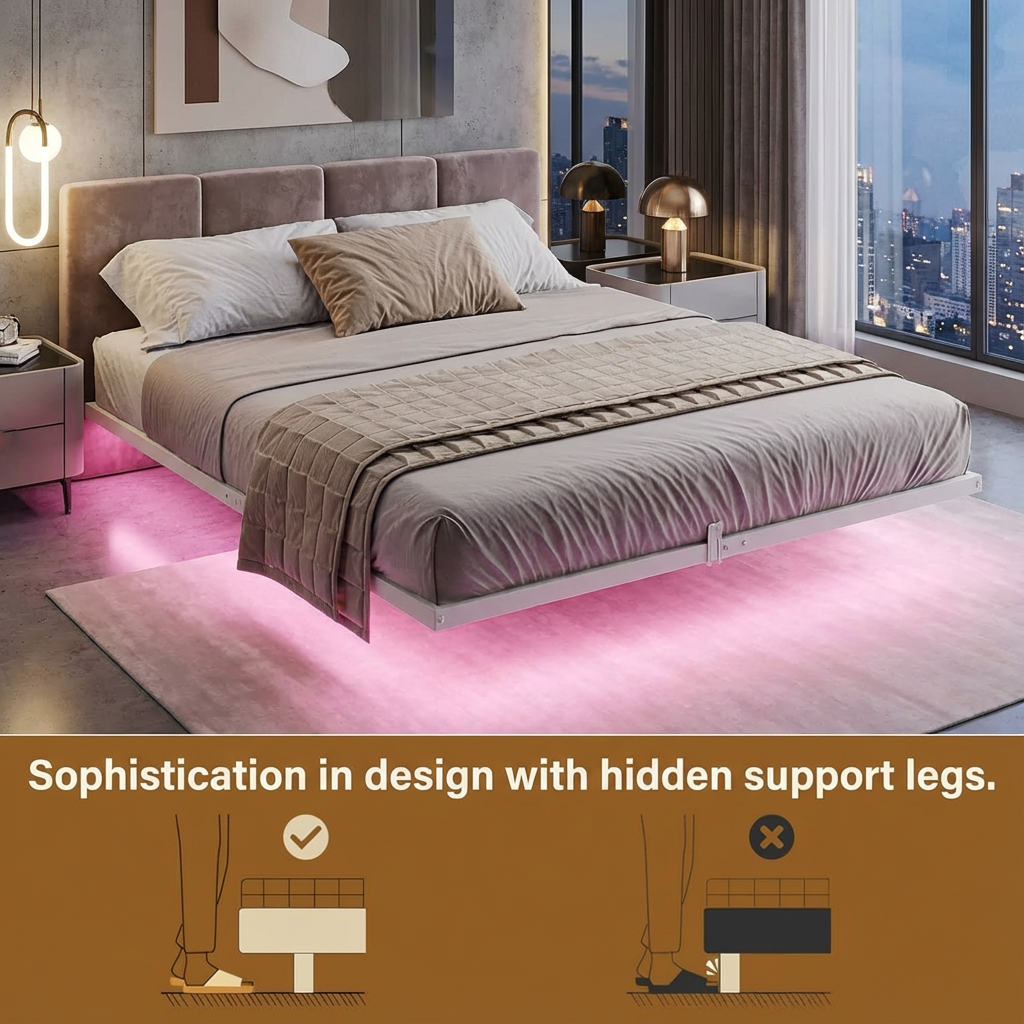

3. Prototype & Sample Production

After technical validation, we move to prototype production—a crucial stage where design meets reality. Skilled craftsmen combine precision engineering with manual finishing to produce a sample that accurately represents the final product.

During this stage, clients can request adjustments to size, color, or structure. Our flexible sampling process allows quick modification without affecting lead time. Each prototype is reviewed for:

Stability and structural safety

Surface finish and craftsmanship

Ease of assembly

Packaging compatibility

This ensures that the sample not only looks right but also performs flawlessly.

4. Quality Review & Client Feedback

Before moving to mass production, we conduct a comprehensive quality inspection. The sample is tested for load-bearing performance, coating adhesion, and environmental durability. Clients are then invited to review the finished prototype through detailed photos, videos, or on-site visits.

Feedback is highly encouraged—we see this stage as a collaborative refinement process. Any necessary updates are implemented immediately to guarantee satisfaction and readiness for production.

5. Ready for Production

Once the sample is approved, we prepare for full-scale production. This includes tooling setup, material procurement, and production scheduling. Our advanced production management system tracks every step, ensuring consistent quality and efficient lead time.

At Delux Furniture, we don’t just manufacture furniture—we engineer trust. Our goal is to help clients turn creative ideas into market-ready products with precision, efficiency, and reliability.

Why It Matters

From sketch to sample, every step of our process is designed for flexibility, transparency, and quality assurance. For importers, wholesalers, and brand owners, this means fewer risks, faster response times, and products that truly reflect their vision.

At Delux Furniture, innovation begins with collaboration—and every great design starts with a sketch.