Understanding the engineering behind a modern floating bed is essential before introducing products such as a floating bed queen or floating double bed into retail or online assortments.

Despite the visual illusion, a levitating bed does not rely on suspension or complex mechanisms. Instead, stability comes from intelligent structural design that balances load distribution, concealed support, and material strength. When engineered correctly, a levitating bed frame can perform just as reliably as a traditional platform bed.

The Core Structure of a Levitating Bed Frame

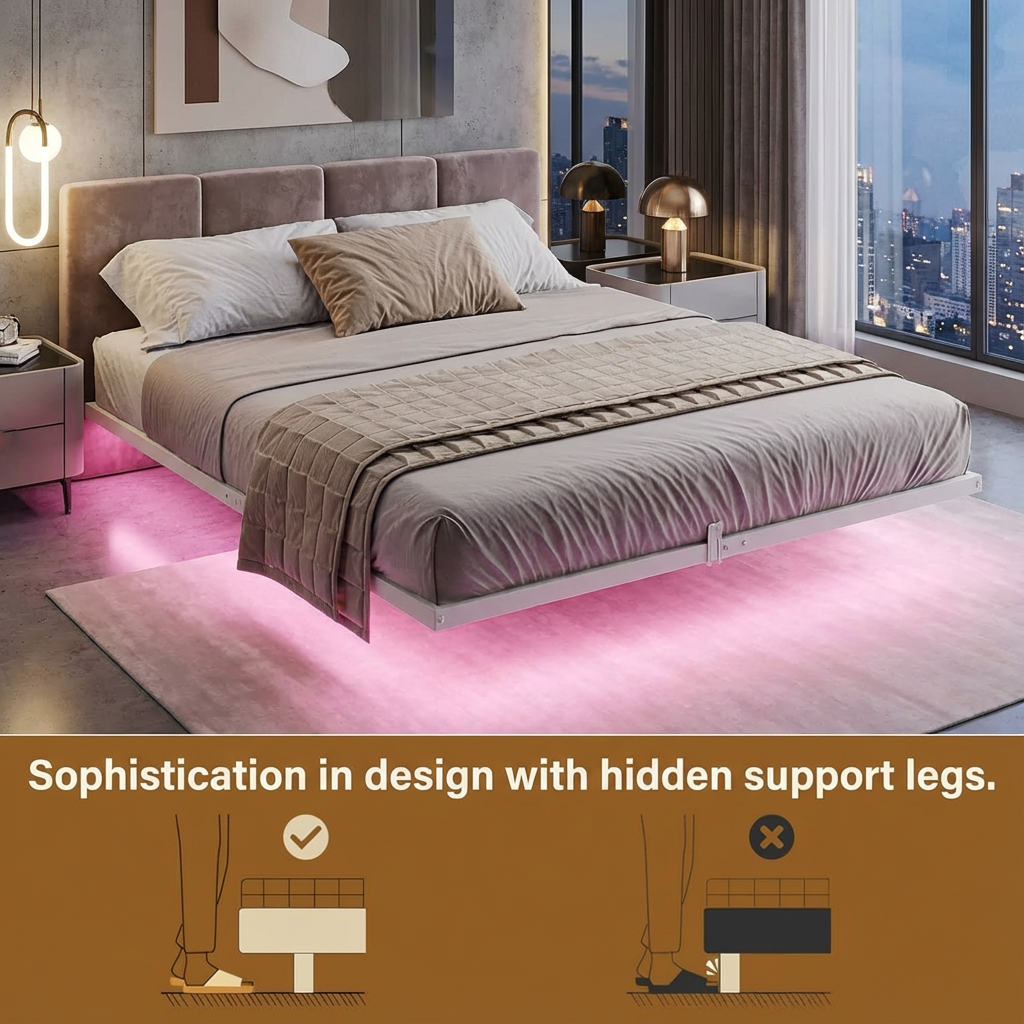

At the heart of every levitating bed is a reinforced base system. The visual “floating” effect is created by shifting the main support inward, away from the bed’s outer edge. This allows the frame perimeter to remain visually suspended while the load is transferred vertically to the floor through hidden legs or a central platform.

In a modern floating bed, the internal steel frame plays a critical role. Crossbars and longitudinal beams ensure that pressure from the mattress and occupants is evenly distributed. This structural logic applies equally to a floating bed queen and a floating double bed, allowing manufacturers to scale sizes without compromising performance.

Unlike experimental floating bed frame DIY concepts seen online, professional levitating bed frames are engineered for repeatability, consistency, and safety under daily use.

Stability: Why Floating Does Not Mean Unstable

A common misconception is that a levitating bed is inherently unstable. In reality, a properly designed levitating bed frame often feels more rigid than lightweight traditional frames. The reason lies in the centralized support geometry, which minimizes lateral movement and eliminates unnecessary flex.

For B2B buyers, especially importers serving European and North American markets, stability testing is a critical requirement. Modern floating bed designs are evaluated for static load, dynamic movement, and long-term durability. Whether configured as a floating bed queen or a floating double bed, the same stability principles apply across the product line.

Support Systems Hidden from View

Support is the defining element of any modern floating bed. Hidden legs or recessed base platforms are positioned strategically beneath the sleeping surface, invisible from normal viewing angles. These components carry the full load of the bed while preserving the levitating appearance.

For larger formats such as a floating bed queen, additional internal reinforcement is often added to ensure balanced support across the entire frame width. This makes the design suitable for both residential and hospitality applications, where safety margins must be higher.

From a manufacturing perspective, this concealed support system allows for efficient flat-pack design and optimized shipping without altering the levitating aesthetic.

Safety Considerations for Commercial Markets

Safety is not optional in B2B furniture sourcing. A levitating bed intended for mass distribution must meet clear safety expectations, including edge stability, anti-tip resistance, and noise control. High-quality levitating bed frames are designed with precise tolerances to prevent shifting during use.

In addition, surface finishes, welding consistency, and fastener placement all contribute to the overall safety profile. These details are especially important for a floating double bed, which may be used in guest rooms, rental properties, or shared living spaces.

Market Demand and Commercial Value

The growing demand for modern floating beds is driven by visual differentiation and perceived value. Online sellers benefit from the striking presentation of a levitating bed, while importers appreciate the ability to position the product as a premium yet structurally sound solution.

By offering multiple configurations—from floating bed queen sizes to double formats—brands can address diverse market needs using a shared engineering platform. This reduces development cost while maintaining design consistency across collections.

A Reliable Platform for B2B Projects

A well-designed floating bed base is not a design risk—it is a proven engineering solution. When stability, support, and safety are addressed at the structural level, products such as a levitating bed, modern floating bed, or floating double bed become reliable, scalable options for B2B buyers.

If you are evaluating floating bed structures for OEM, private label, or custom bedroom furniture programs, early discussion around engineering and safety standards can significantly streamline development and reduce long-term risk.

Our team is available to support product planning, customization, and structural evaluation based on your target market requirements.