Inside the Factory: The Five Core Processes of Steel-Wood Furniture Production

In today’s furniture market, steel-wood furniture has emerged as a mainstream product thanks to its durability, minimalist design, and adaptability to multiple settings. From best-selling storage racks,computer desk,metal bed,bookshelf on e-commerce platforms to practical desks and chairs for office and educational environments, steel-wood furniture is meeting the needs of both B2B clients and end-users worldwide.

However, high-quality furniture is never achieved overnight. A closer look inside a mature steel-wood furniture factory reveals that every product goes through a series of rigorous and detailed processes. From raw material selection to final packaging, each step directly affects product quality and customer experience. Here, we invite you to step inside the factory and explore the five core production processes of steel-wood furniture.

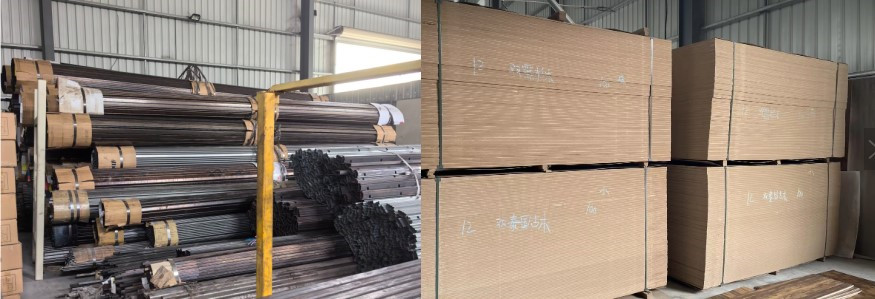

1. Raw Material Selection and Preparation

The foundation of high-quality steel-wood furniture lies in the strict control of raw materials.

Steel: Cold-rolled steel or carbon steel is commonly selected, tested for strength, toughness, and corrosion resistance. To meet international market requirements, the steel also undergoes environmental compliance testing to ensure it meets standards such as RoHS or REACH.

Wood/Boards: We use eco-friendly particleboard and medium-density fiberboard (MDF), often finished with wood grain paper or melamine film for aesthetics and wear resistance. The boards are FSC-certified, aligning with sustainable supply chain standards.

Before entering the production line, all materials are carefully inspected and coded to ensure consistency in the subsequent stages.

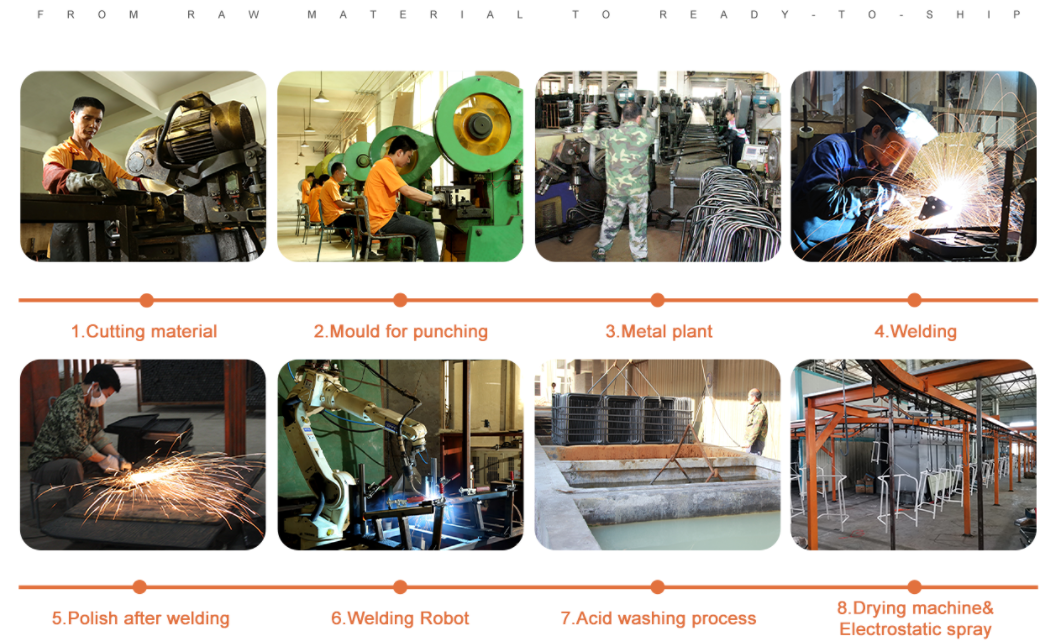

2. Steel Cutting and Forming

The structural strength of steel-wood furniture largely depends on its steel framework.

Cutting: Automated laser cutting machines process steel tubes and plates with a dimensional accuracy of ±0.5mm.

Stamping & Bending: Certain components undergo stamping or bending for structural strength and aesthetic design.

Robotic Welding: Our factory employs advanced robotic welding systems to achieve high-efficiency, precise welds. Compared with manual welding, robotic welding ensures both consistency and clean, smooth seams, while significantly boosting efficiency and reducing defects.

Polishing: After welding, manual polishing is carried out to further refine surface smoothness.

This stage determines the product’s load-bearing capacity and structural stability, making it a critical step for quality assurance.

3. Surface Treatment

The surface treatment of steel parts plays a decisive role in rust resistance and coating durability.

Acid Pickling: Before powder coating, the steel tubes undergo a professional pickling process to thoroughly remove dirt, oil, and oxide layers. This ensures a perfectly clean surface for coating adhesion. With this treatment, we can guarantee that the paint will not peel or chip for at least five years under normal conditions.

Powder Coating: Using electrostatic spraying, powder coatings are evenly applied and then cured at high temperature, forming a robust protective layer. Compared to traditional paint, powder coating is more eco-friendly, and provides superior wear resistance and corrosion protection.

Color Options: Black and white are the most popular finishes, but we also offer customized colors to meet client requirements.

Surface treatment not only enhances the appearance of steel-wood furniture but also extends its service life, ensuring compliance with international export standards.

4. Woodworking and Finishing

The wood component is the key visual element of steel-wood furniture and the most direct touchpoint for users.

Cutting & Edge Banding: Boards are cut with CNC panel saws, then sealed with automated edge banding for a smooth finish.

Drilling & Slotting: High-precision CNC drilling ensures accurate hole alignment for hardware fittings, preventing instability or loosening.

Surface Finishing: Options include melamine laminates or PVC films, providing versatile style choices to match diverse markets.

This stage showcases the craftsmanship and aesthetic detail of the furniture, directly influencing the end-user experience.

5. Assembly, Quality Control, and Packaging

After steel and wood components are processed, they move to the final stage of assembly and quality control.

Pre-Assembly: Trial assembly is conducted to ensure all screw holes and fittings align perfectly.

Quality Testing: Tests include load-bearing assessments, dimensional checks, and surface inspections, ensuring each item meets export-grade standards.

Packaging: Products are packaged in flat-pack (knock-down) cartons with EPE foam or paper corner protectors, accompanied by detailed assembly manuals. This packaging method reduces shipping costs while ensuring safe long-distance transport.

From raw material selection to final packaging, steel-wood furniture undergoes multiple precise steps such as cutting, welding, pickling, powder coating, woodworking, quality inspection, and flat-pack preparation. For B2B clients, understanding this process not only builds confidence in product quality but also provides a clear basis for informed sourcing and partnership decisions.

With the ongoing development of automation and eco-friendly production technologies, steel-wood furniture manufacturing will continue to become more efficient, sustainable, and globally competitive. We welcome you to join hands with us for mutual growth and long-term cooperation.